‘Made in Italy’: high fashion or high-risk?

The cost of noncompliance isn’t just a buzz phrase in responsible sourcing. The repercussions of hidden risks in supply chains and the consequences of lack of supplier visibility are increasingly pronounced. Previous notions of ‘safe’ sourcing markets are now obsolete, as every hub poses critical supply chain sustainability risks that leave businesses vulnerable to reputational backlash and costly disruptions resulting from human rights violations. Italy, for example, perhaps a previously assumed low-risk market, is under heightened scrutiny following allegations of worker exploitation connected to at least 13 high-end fashion firms.

These allegations follow several others in recent years, as Italy’s luxury and industrial sectors have been called out for reported unethical manufacturing practices. Reports allege issues surrounding conditions for migrant workers, inhumane treatment and health and safety issues, all of which were signaled by EiQ’s risk insights over the past five years. While reports say the companies do not currently face civil penalties, prosecutors want to assess if the companies are directly involved in the use of exploited labour and if their compliance and governance models are adequate to prevent abuse, highlighting the importance of improving visibility and risk management across supply chains.

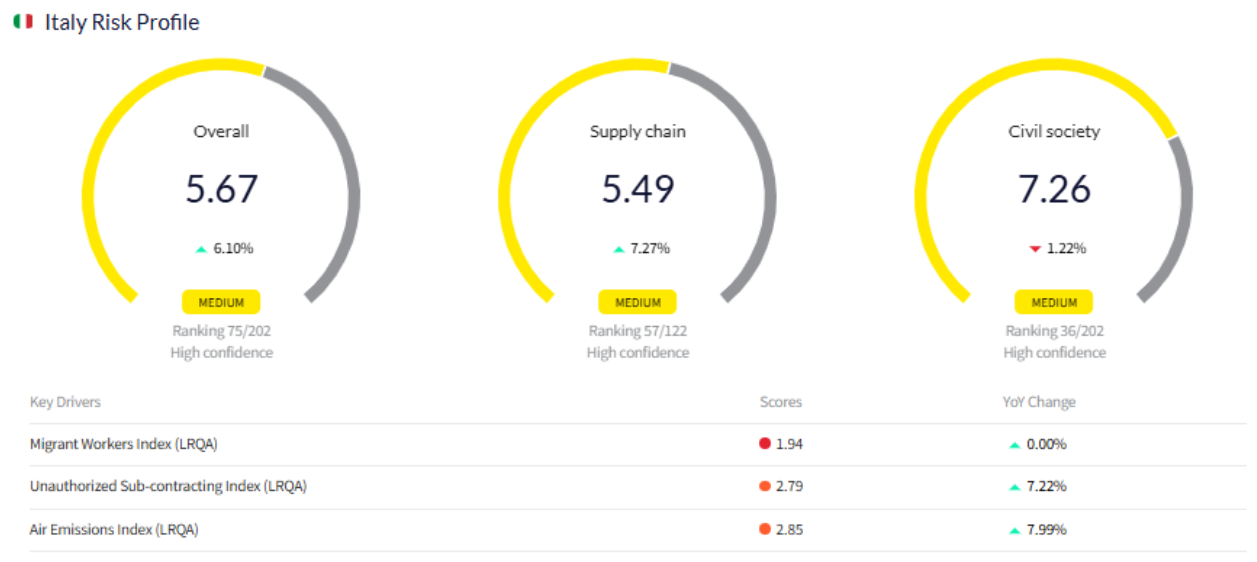

Early warning signals alert of exploitative trends from suppliers in Italy in recent years

Onsite audit data in EiQ has signaled critical risks in Italy for at least the past five years. EiQ’s forced labour risk index, which assesses the inherent risk exposure based on prevalence of audit findings, noted Italy as high-risk since 2020, along with risks of inhumane treatment and high prevalence of foreign migrant workers, which are often more susceptible to exploitative treatment. The Italian government recently announced approval of roughly half a million work visas for foreign nationals over the next three years, expanding the population potentially vulnerable to exploitation if controls are weak.

The issue of unauthorised subcontracting has also been prominent in Italy, according to EiQ data. Subcontracting practices remain prevalent throughout supply chains but can heighten risk exposure, as suppliers may outsource production to facilities that are less aligned to responsible sourcing standards. This can often obscure labour conditions where abuses tend to proliferate. Unauthorised subcontracting has shown high or extreme risk in Italy year-on-year, and is a key issue reported in recent media reports. These covert practices and rapid subcontracting shifts may be difficult to detect in standard annual audits, leaving businesses vulnerable to unexpected disruptions and reinforcing the need for a more holistic approach to supply chain due diligence. Enhancing foresight through improved data and on-the-ground expertise is needed to understand, evaluate and mitigate highly vulnerable areas and target them with intent and the right resources.

Lessons from the fashion industry’s oversights

More than half of businesses have faced penalties or fines for responsible sourcing violations, according to a recent survey conducted by EiQ deployed across 600 sourcing and procurement professionals.1 This figure highlights that media headlines are not a one-off, and companies must transform their risk management practices to avoid the costly outcome that comes from missing the critical risk areas associated with their supply chains.

Hidden risks, especially those buried in deep tiers, informal workshops, or unauthorised subcontracting facilities, can undermine even the most diligent compliance programmes. Therefore, we understand that blind spots must be addressed through tailoring your risk management approach for the specific vulnerabilities in your programme to achieve the agility and resilience needed to address these hot spots.

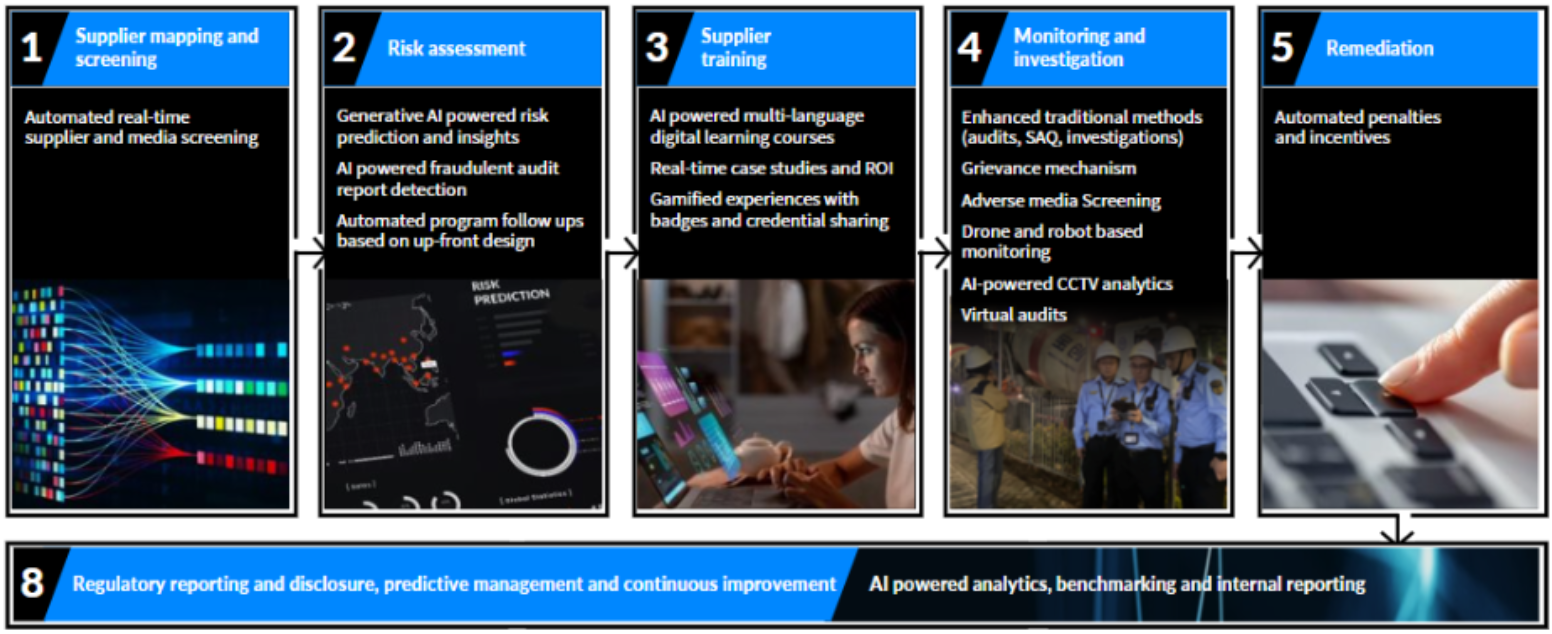

This shift will require teams to prioritise quality data, implement the right technology – including leveraging AI and optimising its capabilities – becoming more proactive, achieving ongoing monitoring, deploying the right corrective action and remediation, leveraging the right expertise from assessment and advisory teams and finally, shifting away from the blanketed approach that no longer serves the unique needs of your supply chain and its critical issues.

The optimised due diligence workflow with EiQ and LRQA

Foundational measures to start the transformation journey can include:

- Understand your supply chain: Get the full risk view and identify which areas are most vulnerable to exposure.

- Prioritise hotspots: Focus interventions where indices are high or worsening.

- Monitor shifts: Track year‑on‑year changes to detect systemic deterioration early.

- Align your supply chain: Implement tools like supplier training to promote site improvement and align partners on standards and regulations.

Don’t wait for your supply chain risks to become headlines

Hidden risks are the core vulnerability in Italy’s fashion supply chains, and supply chains around the world. It’s now imperative that businesses evolve from an audit‑led paradigm to an intelligence‑driven, autonomous due diligence model. EiQ exists to make that shift actionable by surfacing the signals, quantifying the exposure and guiding targeted mitigation before the headlines do.

EiQ has alerted Italy’s high exposure of forced labour risk, migrant worker indicators, and persistent unauthorised subcontracting violations well before the latest investigations. These signals cannot be ignore and could be the difference between reputational damage control and responsible sourcing resilience by design.

1 Full survey results to be released in Q1 2026

Related Posts

Discover more insights from our blog.

EiQ welcomes Selcuk Buyukozer to Advisory Board

Buyukozer joins EiQ’s Strategic Advisory Board, bringing 25 years of sustainability experience to help advance its mission of transforming supply chains through data and innovation.

Digitalise corrective actions and enhance visibility with EiQ CAP management

Digitalising CAP workflows is a strategic step toward resilient, transparent supply chains.

What do we mean by autonomy in responsible sourcing?

A vision for the future of risk management with AI